The Solution.

Mantiscan provides a cutting-edge technological system that solves the challenges oil and gas companies face through installation on each platform. By teaming with us, oil and gas companies can stay ahead on required inspections and reports without sending workers out to handle them.

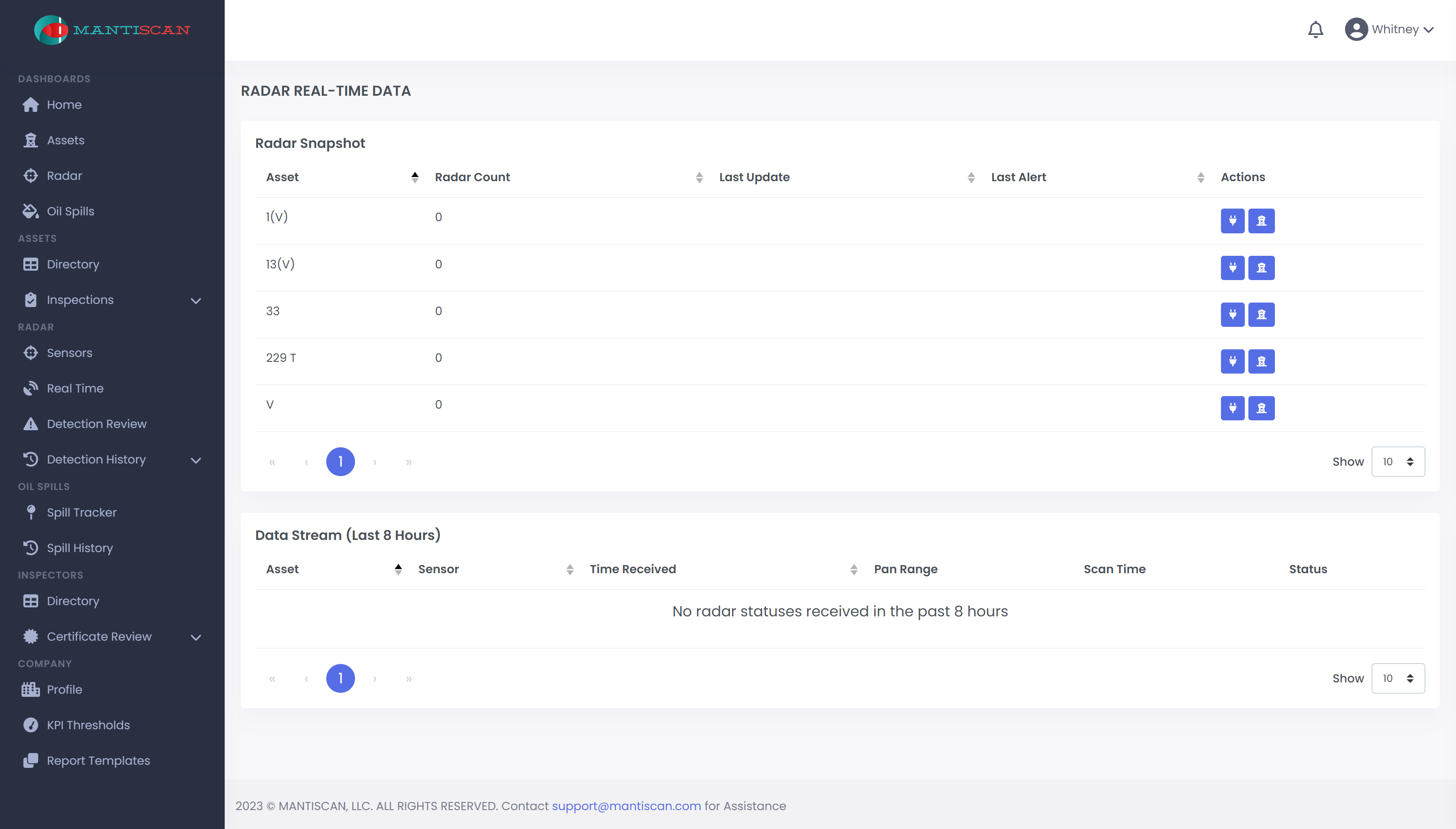

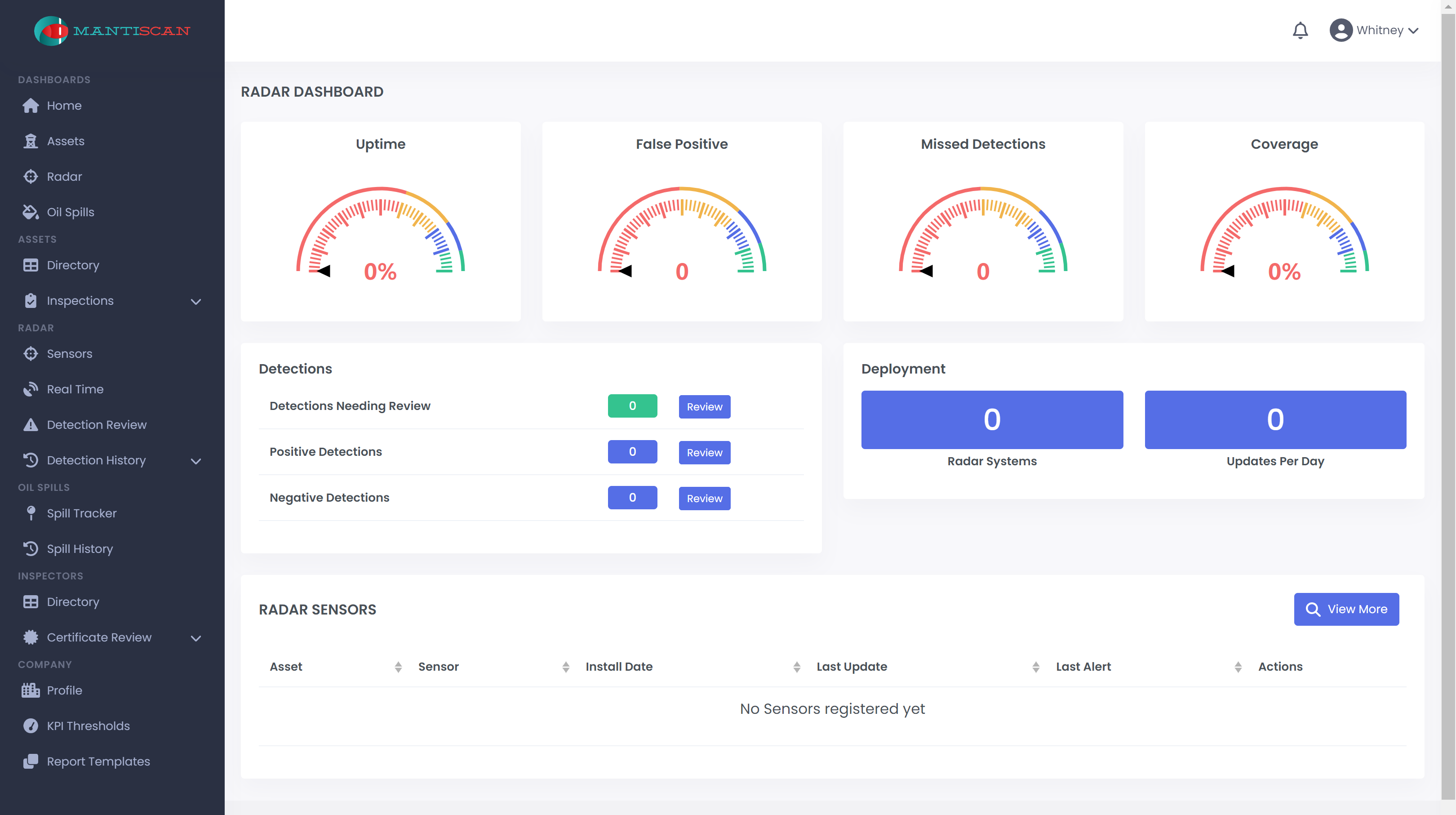

Environmental Radar System (ERS)

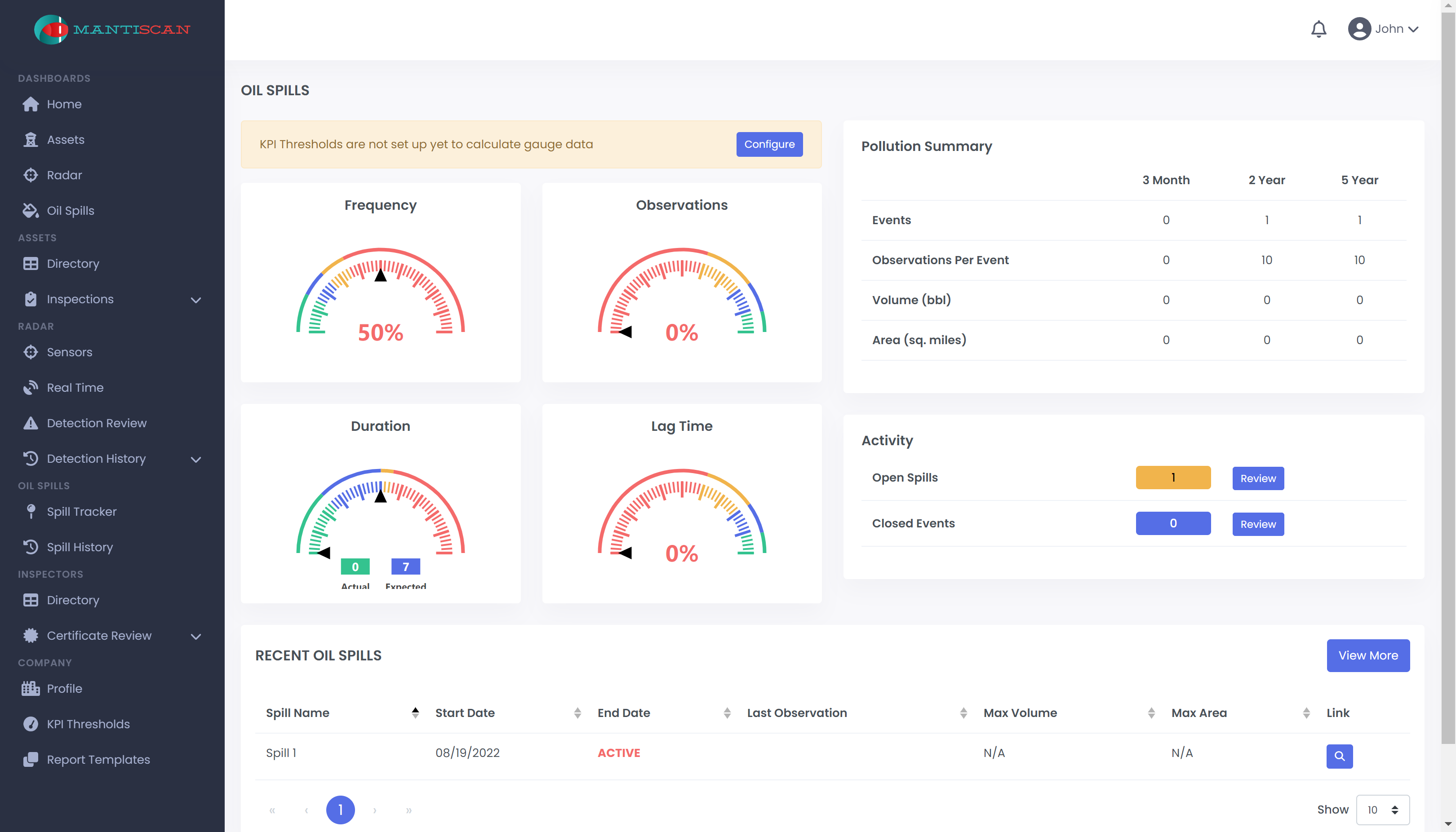

- ERS is the leading solution for oil on water detection with a 360-degree day and night situational awareness of any incursion that may threaten ocean assets including leaks, fires, or trespassing personnel.

- Provides the assistance of a fully automated monitoring system and deep-learning software that can detect threats, such as hydrocarbons, leaks, spills, and more, through infrared cameras.

-

The system uses real-time polarized long wave infrared (LWIR) providing up to 400% better detail and contrast than other solutions alone and a detection range of oil on water up to 1,500 m (.93 mi).

ERS provides more confidence with 99% detection accuracy.

Monitor

White Glove Program

On-site service team installs ERS on platforms.

Dual Sensor

Multiple ground sensors available to the operator for real-time monitoring.

Multiple Monitoring Techniques

Ground sensors combined with satellite data provides insights from multiple locations for the most accurate storm assessment and leak monitoring.

Detect

24/7 Monitoring

360-degree day and night remote leak and fire detection without the need for site visits.

Alert

Customizable alerts set for predetermined thresholds to keep the person in charge (PIC) informed without false alarms.

Improve Over Time

Reduce

Automated Reporting

Reduce the administrative burden of filing regulatory reports by automating report building.

Burden Hours

Reduce the need for over 3,786 inspection visits and over 300,000 burden hours filled with high labor and transportation costs.

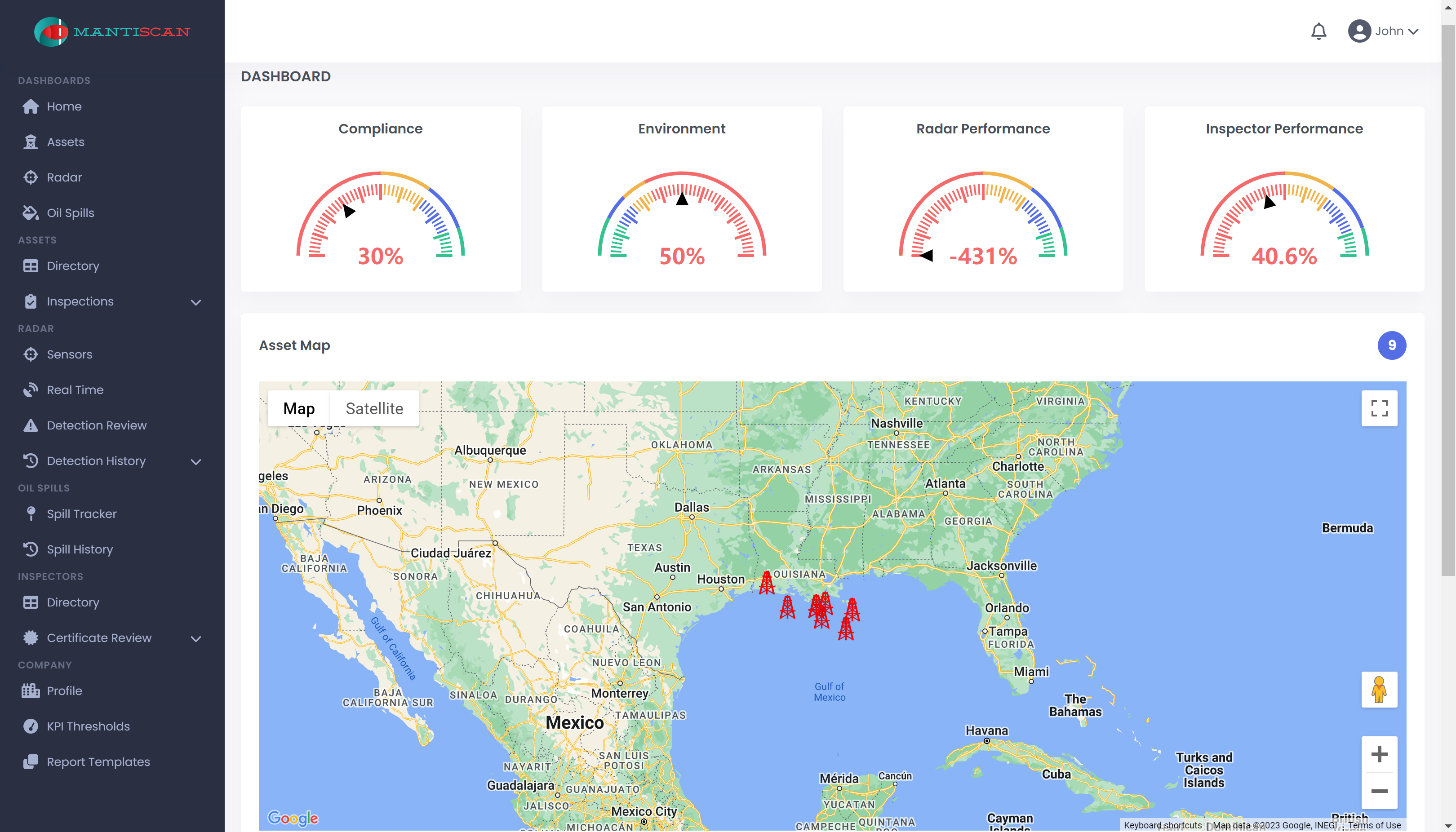

Key Performance Indicators

Reduce unplanned downtime by applying advanced analytics to become more predictive.

ERS software is a comprehensive solution, combining multiple sensor technologies for robust detection, AI algorithms, and automated reporting to alleviate the administrative burden on operators so they can focus on supplying us with the world’s energy.

Inspect

-

ERS replaces the current costly solution of onsite visits via vessel or aircraft.

-

If an incident occurs, the person in charge (PIC) receives an alert. The PIC can log in from anywhere in the world to confirm visually in real-time if there is an incident that needs immediate attention.

-

If maintenance or remediation is necessary onsite inspections can be scheduled through the app.

Measure

- The detection algorithms pass through multiple checks to eliminate false alarms.

-

Areas of interest (AOI) can be determined by the operator for a programmed scan to ensure optimal detection.

-

Our AI is designed to improve over time, ensuring the quantity and location of the spill.

Report

- Inspectors have access to the digitized reports through the user-interface.

- Reports can be automatically sent to whatever end user the operator desires.

- As we digitize the reporting process with operators and ERS AI learns the asset, reporting will become completely automated.

Performance

-

By combining ERS with operators current SCADA systems it provides complete visual and situational awareness of their assets.

-

Operators will build more efficient maintenance plans over time using the analytics provided by ERS.

-

ERS will cut operators’ visual inspection costs in half.